Boox Delivers Sustainable E-commerce for the Next Generation

A deep dive into the world of reusable e-commerce packaging with Matt Semmelhack, CEO and co-founder of Boox.

Boox, a cutting-edge climate tech startup founded by Matt Semmelhack, is busy revolutionizing the world of sustainable e-commerce packaging. Matt and his team aim to eliminate single-use waste by supplying their reusable packaging to e-commerce brands.

In this interview, Matt shares his journey from working at Thistle, a plant-based meal delivery subscription company, to founding Boox as a way to realize his aspirations of combating climate change and leaving the world better off for his children.

Matt and I delve into Boox's mission, how they help e-commerce companies strive for sustainability, and the challenges of creating a circular economy in the age of e-commerce. By replacing cardboard shipping boxes with reusable polypropylene boxes that can be returned and then reused, Boox is paving the way for a future where waste is greatly reduced and managed more sustainably. The company has already reached product-market fit and is now looking to evolve further to scale its sustainable e-commerce packaging globally.

Jacob Sheldon: In your words, what does Boox do?

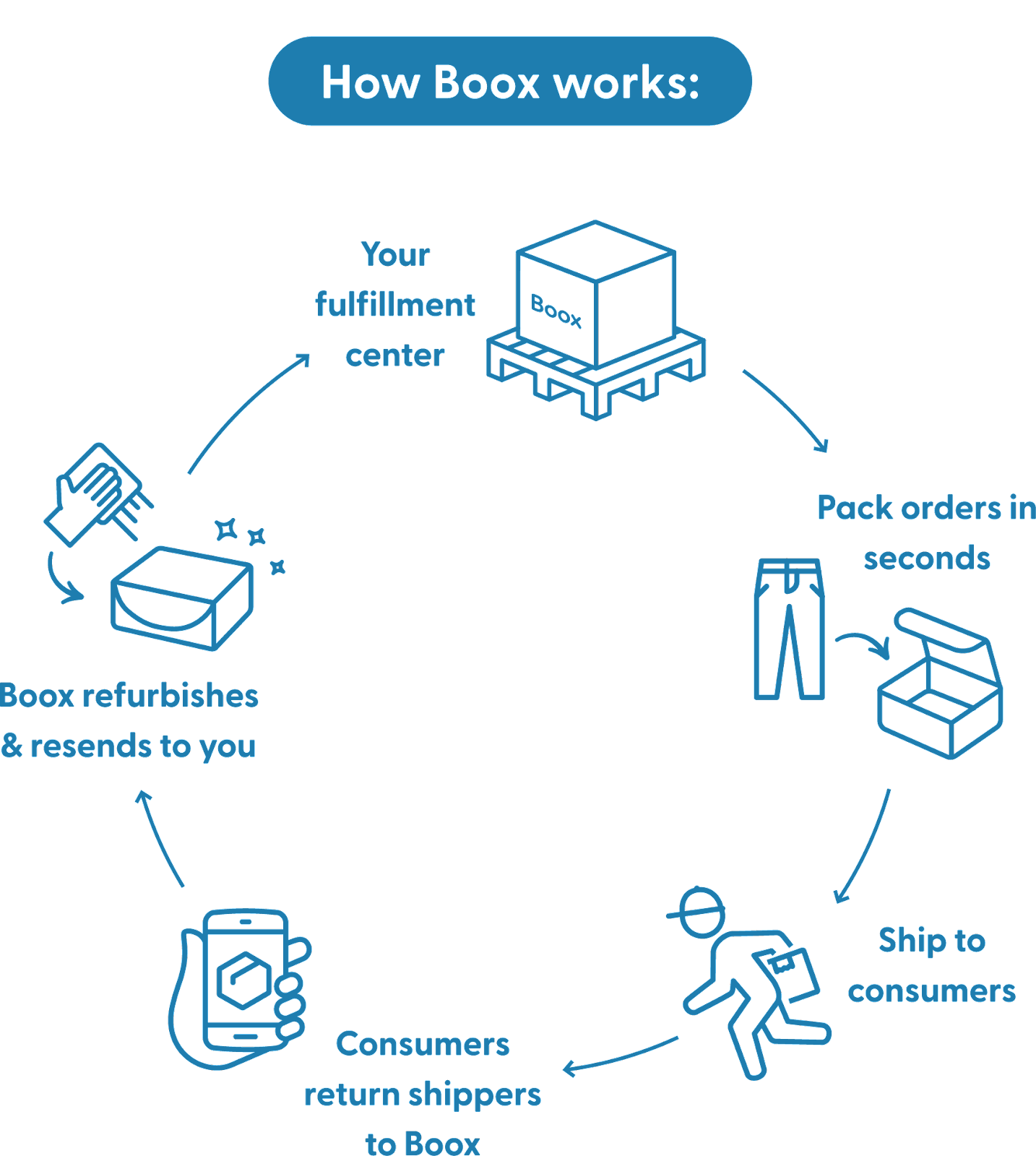

Matt Semmelhack: Boox supplies reusable boxes and other types of packaging to e-commerce brands. We enable the circular economy for e-commerce brands, starting with reusable packaging. Our mission is to eliminate single-use waste. Although today we primarily supply reusable packaging, what we're building is an ecosystem of circularity and reuse for brands, as well as the end consumers.

Jacob: What led you to start Boox?

Matt: I was working at a company called Thistle, a plant-based meal delivery subscription company. It was my first time working for a mission-driven tech company. I had previously worked in restaurants and opened a few in San Francisco, but I got the bug to work for a company with a bigger mission and growth trajectory. Thistle had a written mission statement related to climate change, which inspired me to focus my career on that issue. I appreciated their approach, which was about helping people eat more plants, making it easier to eat less meat, and not mandating veganism.

While working at Thistle, I found that a surprising number of people were canceling their subscriptions because of the trash that came with the meal kits. Customers complained about the waste and questioned the company's commitment to reducing climate change. I proposed that transitioning to reusable packaging could reduce waste, lower costs, and make customers happier, and I did some research to demonstrate the long-term financial benefits. The founders loved the idea but also recognized (rightly so!) that the effort required was a whole separate business, not an internal project. So, I left Thistle and started Boox.

The other big reason is my kids. My wife and I have three children, and they are the driving force behind my passion for Boox. I believe in leaving the world a better place for the next generation, and I want to invest my time in something potentially world-changing. Boox aims to fundamentally change the system of waste management. The dream is that, in 10 years, my oldest daughter will never receive a single-use package in the mail. It's a challenging goal to reach, but that's what we're striving for.

Jacob: When you think about your clients, what is the problem you're solving for them?

Matt: Just to clarify, when I say "consumer,” I mean the end user receiving a box, whereas our “client” is a brand that sells and ships products to its customers. Regarding our clients, they're trying to achieve three things:

Delight their customers with a better, more eco-friendly experience.

Make it easy for them (both the company and end users) to reduce their impact.

Make more money or reduce costs.

The way we help them achieve the third goal is more complicated than the others. Over the past 20-25 years, consumer preferences have changed. When I was a kid, we didn't choose brands for their sustainability, but now that’s becoming much more important. Only a few brands, like Patagonia, championed sustainability from the beginning. Today, if a brand doesn’t market its sustainability efforts, they’re the outlier, and customers are less likely to buy from them–that wasn’t true 20 years ago. What we do for brands is help them be more sustainable and demonstrate that to their customers at the same time.

Jacob: It's interesting that what has become an opportunity for these brands has now become a problem. Is that simply due to the increase in e-commerce?

Matt: Yes, 100%. The timeline of gross amounts of packaging arriving at your doorstep is directly correlated with the rise of e-commerce. About 25 years ago or so, when people started using the internet, they immediately started buying things online. Digitally, native brands without storefronts had to get really good at shipping things quickly. This led to increased packaging and merchandise returns that had to be processed and shipped back.

Twenty-five years ago, most people went to stores to buy products. Items picked up off the shelf at a store like Target might have primary packaging but would not need secondary packaging or a shipping box with void fill. Now, every single product has all this packaging because it is shipped in the mail and needs to be protected. The responsibility for dealing with that new and excess waste has shifted from the retail stores to individual consumers and their local waste management infrastructure.

Despite the exponential growth of e-commerce over the last 25 years, the infrastructure to deal with its waste hasn't evolved very much. Landfills, garbage trucks, and bins remain essentially the same. The right solution isn't just larger recycling bins; that's just a band-aid, not an actual long-term fix.

Jacob: So, speaking of trash and recycling, tell me how Boox's solution is better than recycling.

Matt: We've evolved our idea to clarify that we're not anti-recycling. The hierarchy we learned in grade school- Reduce, Reuse, Recycle- still holds. The number one way to lower the amount of garbage is to buy less stuff. However, that's only sometimes possible. We need things, and it's easier to get them online today compared to 20 years ago. We can't just stop buying things online; it’s not a solution.

Recycling is effective for certain materials, but if those things are designed to be reused, it will reduce the number of things you need to buy. A circular economy extends the life of an item, leading to fewer items being bought over time.

Our Boox boxes and any products we design are intended to be reused first. Second, they're designed to be recycled. It's not just about reusing and not recycling; it's about reusing as much as possible and recycling only when it’s absolutely necessary. There's an ongoing debate about whether recycling a box back into another box is true recycling or "downcycling" if it's made into a lower-value item with a shorter lifespan. Ultimately, at Boox, our focus is on responsibly promoting reuse first, then recycling.

Jacob: Tell me about how much your boxes are reused before they're recycled.

Matt: The reuse rate varies wildly, and we're transparent about the fact that there’s a way to go before we fully solve this problem. There are many types of e-commerce brands and business models, some of which are more easily adapted to the circular economy than others. We've designed something that works for as many as possible, but it works much better for certain ones than others.

Rent the Runway is an excellent example of a business designed for circularity with its sharing economy and reuse across many users. However, this model is unusual and does not represent how most e-commerce works. Our target is the much larger group of brands, where products are shipped from a fulfillment center to the end user without the expectation or incentive of returning. That's why the return rate is important, but the ability of our packaging to be recycled is also crucial since the return rate is less than 100%, and we don't expect it to be anytime soon. That's a long-winded way of explaining that the reuse rate of our boxes isn't easily quantified and depends on various factors. Broadly speaking, we see return rates between 5 - 50%. The biggest factors that can increase the return rate are incentives to return and engage, as well as awareness/education of the consumer. We work with our clients to help increase the return rate over time using these tools. It's a team effort.

Jacob: Are there carbon emissions related to the return process?

Matt: Certainly, there are carbon emissions related to everything. We measure that through lifecycle analysis, which typically has three parts: production, actual use throughout its life, and end of life or return. For a cardboard box, the lifecycle involves production, shipping to the end user, and then recycling, where the material is broken down and ideally made into another cardboard box.

When comparing the lifecycle analysis of our Boox boxes to that of a cardboard box, the production and use stages are very similar and have almost the same amount of emissions. The crucial part is that, while there are emissions associated with recovering our Boox boxes from the consumer, they are significantly less than those of the recycling process. People often assume that transportation is a big part of a product's lifecycle, but in the case of boxes, it's less than 2%. Transportation in this country is quite efficient– it’s not as though a single Boox box is traveling across the country by itself. They’re being moved in full truckloads as efficiently as possible.

The assumption that once you put something in your recycling bin, it’s immediately turned into another product needs to be revised. In reality, your recycling travels quite a long way before actually being recycled and then goes through many impact-intensive processes before it can be turned into a new product. The emissions from returning our Boox boxes for reuse are significantly less than those generated when something is recycled. When you get a Boox box back, you can reuse it, skipping the production step for subsequent uses. So, if you can use a Boox box multiple times, it's comparable to using multiple single-use boxes, adhering to the reduce and reuse principles.

Jacob: Do you only make cardboard boxes, or do you offer other types of packaging?

Matt: Actually, our boxes are not made out of cardboard. They're made of polypropylene, which is a plastic material. This might raise eyebrows among environmentalists and climate-conscious people but not among circular economy advocates. The reason is that while plastic is often vilified, larger plastic items don't typically end up in oceans or forests. When people think about plastic in the environment, they picture a plastic bottle or bag floating in the ocean, and the concern is that it will “last forever.” This is a problem with the single-use system, not a materials problem. The fact that a material could last forever is an incredible characteristic for within a circular economy.

There's an interesting debate about what should be compostable versus what should be reusable. Some items, like diapers and medical devices, are better off being compostable. Food containers or utensils are another interesting category.

Our Boox boxes are made of polypropylene, and we're steadily increasing the amount of post-consumer resin in the boxes. The goal is to eventually reach 100% post-consumer content. The dream is to pull plastic out of the existing waste stream to make reusable Boox boxes, effectively upcycling the material. By doing so, we could actually achieve a net positive impact by removing plastic that would otherwise be incinerated or sent to landfills and keeping it in the system forever, inside of reusable products. The ideal scenario is for these boxes to circulate indefinitely, fulfilling their purpose over and over again, locking up the carbon contained in the material.

Jacob: With your prototype, it seems that you're already on a path to 100% post-consumer boxes. Do you have a timeline for when you'll be able to reach that goal?

Matt: The target is the end of 2024. The limitation isn't technology or price; it's availability. Our manufacturer can make 100% post-consumer boxes for us today but can't make 10 million of them due to material scarcity. It's both exciting and limiting. As we start to ship millions of these boxes made of this material, we can affect the market. Polypropylene is a commodity, and post-consumer polypropylene is not in excess supply due to a lack of demand. As demand increases, the price will rise, and businesses will start collecting and selling post-consumer material, which will become readily available at scale.

The scale of packaging, with 20 billion shipments in the US and 200 billion worldwide, has the potential to move the needle on the entire post-consumer materials market. By making boxes out of post-consumer material instead of cardboard, we could shift the cost of post-consumer material to the point where waste management companies would be incentivized to collect and sell it to our manufacturer, closing the loop and creating a truly circular economy. It's an exciting possibility, but we have to continue to grow to make it a reality.

Jacob: This is obviously a huge market. Just how large is it?

Matt: These are estimates, but the basic quantities are 20 billion shipments annually in the US, growing at 20% year over year, and 200 billion globally, growing even faster. This only accounts for things shipped in boxes and doesn't include primary packaging, poly bags, or other single-use items. We're working towards becoming the operating system for circularity and reuse in this system rather than just being a box supplier. We would like to have other manufacturers and partners develop reusable packaging that can be returned using the Boox network.

Take this hand cream container, for example. The container itself is recyclable, but not the cap. This item can’t be made to be composted because it would break down during shipping. It needs to be designed for either industrial-scale recycling or for reuse. Our theory is that there's no way to design packaging for reuse without a system in place for its collection.

The packaging market is worth over a trillion dollars globally. The idea is that we'll be able to service all types of reusable packaging once at scale.

Jacob: Tell me about your core team, who's on it, and why.

Matt: My friend and co-founder, Bob Walton, is, of course, crucial to the team. He was at Facebook for a long time and is now our CTO. His validation and willingness to work on the idea with me meant a lot. We have a business development team led by Peter Smith, a design team led by Paige Russell, and a finance and operations team led by Lindsey Martin. We also have operations directors in both the US and the UK. Our team is a combination of operations, growth, and tech-focused members.

An important aspect of our work is that our boxes are tech-enabled, allowing us to recover, track, and measure our impact and return rates. When a consumer receives a Boox box, a QR code inside leads to a digital experience, which shows how to return the box and serves as a promotional marketing moment for the brand that shipped it. The digital component is vital, and Bob's expertise as a front-end engineer helps make it seamless and delightful for consumers.

Jacob: Do you also have a digital experience for your clients?

Matt: The digital experiences we create are branded as the client. For example, if you receive a Boox box from Goop, it'll feel like you're interacting with Goop, but they're telling you how to return the box. In their case, they offer a gift as an incentive to return the box. Our position is that Boox powers other brands' sustainability efforts. We're often mentioned in the digital experience, but the focus is on the client's brand.

At Boox, we make it as easy as possible for our clients to work with us. We collect and share data with them, and we handle all the sustainability analytics and tracking so the client can focus on marketing and selling their products. All they have to do is switch their packaging to Boox.

Jacob: What is one thing that your team does really well?

Matt: The team is excellent at rolling with the punches and adapting quickly to changes, whether they're macroeconomic factors or micro factors. The company was founded during the pandemic, and we've experienced pandemic-related challenges because of that. We've adjusted our branding and focus a few times over the past few years, and the team has been great at reacting, staying positive, and staying focused on the end goal.

Jacob: You have a lot of learnings from starting businesses over the past few years. What's one piece of advice you have for other entrepreneurs?

Matt: Having started 10+ companies, I've experienced various challenges with different types of businesses. My number one piece of advice is to make sure that whatever you're working on gets you out of bed in the morning, and I don't mean just because you're going to make money. The financial rewards will come with working on something impactful that you care about deeply and work hard on. I've told many entrepreneurs and younger people this: care deeply about what you're doing, and everything else will follow. It's been a challenging three years for sure, but it'll work out if you have a good concept and a great product. Nothing impactful comes easily.

Jacob: What's your most persistent issue since starting the company?

Matt: Certainly, the lingering effects of the pandemic have been a significant challenge, impacting various aspects such as in-person meetings and team events. For example, we had our first big event with our entire team, flying people in from other countries, and on the first day, one of our employees informed us that he had COVID. Changed the nature of the entire event. It's been a disruption, especially for a young and nimble company like ours.

Another pandemic-related issue was the massive shortage of truck drivers and sea freight containers, causing delays in shipping our physical products manufactured overseas. When you're trying to be an innovative, fast-moving company, a 12-week delay due to a container coming from China can throw a wrench in your plans. However, this is a once-in-a-generation problem, so it's a positive thing that our biggest challenge is COVID-related– it's our DNA to deal with challenges and to work together to get through them.

Jacob: What about right now? What are you focused on the most?

Matt: We've achieved a high level of product-market fit, and now we're in between being a growth-at-all-costs tech venture-backed company and running a profitable business. We're transitioning towards demonstrating that we can be a sustainable company in both senses: reducing environmental impact and supporting our operations with our profits.

This transition significantly shifts how we behave, act, target clients, and measure KPIs. It's essential for our future, and if we plan to IPO at some point, we need this foundation of well-run operations and profitability.

Jacob: What's your overall goal for the company?

Matt: Our goals are to change how people think about waste, how e-commerce packaging works, and ultimately, how e-commerce operates through promoting circularity. A measurable goal is that once my daughter becomes an adult, she'll never receive a cardboard box in the mail. It will be challenging to achieve, but we believe it’s realistic.

Additionally, we're focused on inspiring the next generation to think more thoughtfully about reducing, reusing, and recycling. By interacting with millions of products and billions of consumers while generating hundreds of millions of impressions on social media, we aim to be a good role model for the next generation. Our message is something we believe in; it’s fact-based, and it aligns with our goal of growing the company quickly.

Jacob: What's the best way for people to connect with you after they read this?

Matt: I can be reached at Matt@boox.eco via email. Our primary communications focus is on our social media, particularly Instagram, which is the best way to follow Boox's progress. We're always looking to connect with like-minded people, whether they're interested consumers, brands wanting to switch to reusables and reduce their impact, investors (although we just raised a round), or reporters who love talking about sustainability.